Fitness for Service (FFS) is a best practice and standard used by the oil & gas and chemical process industries for in-service equipment to determine its fitness for continued service.

A process, plant, and equipment are often exposed to corrosive environments and/or elevated temperatures. Under these conditions, the material used in the equipment can degrade or age with time. When important equipment such as pressure vessels, piping, and storage tanks become older, the plant operator must decide if they can continue to operate safely and reliably to avoid injuries to personnel and public, damage the environment, and cause unexpected shutdowns. Fitness for service assessment procedures provide the means for the plant operator to make appropriate decisions on established engineering principles.

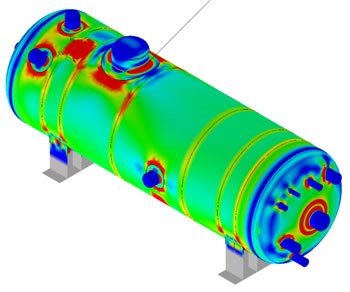

Fitness for service assessment is a multidisciplinary engineering analysis that ensures all process and plant equipment such as pressure vessels, piping, and tanks operate safely and reliably for the desired period of operation and until the next turnaround or planned shutdown occurs in the future. ASME, API, BS 5500 & other recognized design codes provide rules/guidelines for a general procedure for assessing fitness for service. This assessment procedure evaluates the remaining strength of the equipment in its current state that may have degraded from its original condition. Common degradation mechanisms include corrosion, localized corrosion, pitting and crevice corrosion, hydrogen attack, embrittlement, fatigue, high-temperature creep, and mechanical distortion.

Fitness-for-service assessments evaluate the structural integrity of components and their suitability for continuous service. Procedures such as BS 7910:2013, API 579/ASME FFS-1, ASME B31G, DNV-OS-F101 and FITNET enable the integrity of critical pressure components and welded structures to be assessed against different failure modes, using a validated engineering approach.