Welding defects can compromise the stability and integrity of a welded structure. When you need confidence in testing of welds, Time of Flight Diffraction (TOFD), a high-performance non-destructive testing (NDT) technique offers you accurate detection and sizing of cracks, slag and lack of fusion in true wall direction which will enable to access the life of the vessel. We accompany you throughout your testing project and offer you individual solutions.

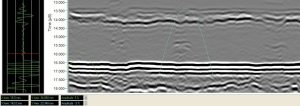

In TOFD, longitudinal waves generate between two ultrasonic sensors to detect, locate, and size flaws based on the time of flight of any diffracted beams. U-SONIX’s utilizes TOFD to inspect weld volume including heat-affected zones and in-service components to determine asset integrity

How ToFD Works?

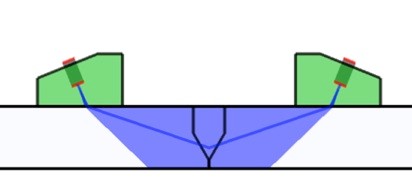

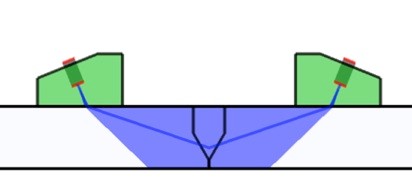

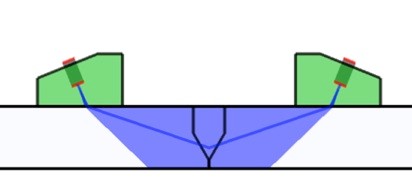

ToFD is an innovation of ultrasonic testing which consist of two probes. One will act as a transmitter and other one is receiver. Instead of recording the ultrasound that is reflected by defects, it detects diffraction of sound waves that emanate from the tips of a defect. ToFD inspection provides accurate information about the length and height of defects. Unlike other testing methods, ToFD can detect flaws regardless of its orientation.

TOFD differs from conventional pulse echo ultrasonics in that it depends on diffracted energy rather than reflected energy being a non-amplitude-based technique. TOFD, however, relies on time-based, low energy, diffracted signals from the tips of flaws, allowing an exact or absolute position and size for the flaw to be measured and imaged. The technique is accomplished by using two probes, a transmitter and a receiver; normally placed either side of the weld joint or area to be examined. Because the technique is not amplitude dependent, as in conventional ultrasonics, it does not suffer from the constraints of probe location to flaw orientation, poor coupling, uneven or changing material surfaces. TOFD also uses longitudinal wave only, allowing mode converted signals to be screened out, simplifying the characterization and positioning of flaws. Data from the scan is collected in ‘raw’ form and digitized in RF format (‘A’ Scan).

Merits of Time of Flight Diffraction (ToFD)

+91 63839 92501

admin@u-sonix.com